Setup Strategies

General

This chapter provides you with strategies for the commissioning of the

digital servo amplifier and the optimization of its control loops.

These strategies cannot be universally valid. You may have to develop your

own strategy, depending the specification of your machine.

However, the sequences that are presented here will help you to understand

the basic methodology.

Parameterization

|

|

The manufacturer of the machine must create a risk assessment for the machine,

and is responsible for the machine with regard to functional, mechanical

and personnel safety. This applies particularly to the initiation of movements

with the aid of commissioning-software functions.

The commissioning of the

servo drive with the aid of Setup software functions is only permitted

in combination with an interlock device according to EN 12100, that operates

directly on the drive circuitry.

|

-

The servo amplifier is installed, and all the necessary electrical connections

have been made.

-

The 24V auxiliary supply and the 208V...480V main power supply are switched

off.

-

A personal computer, with the commissioning software installed, is connected.

-

An interlock device according to EN12100 is connected.

-

The controls provide an LOW signal for the ENABLE input of the servo amplifier

(Terminal X3/15), i.e. the servo amplifier is disabled.

Switch on auxiliary supply

|

1.

|

Switch on the 24V auxiliary supply for the servo amplifier.

LED display: X.XX (firmware version)

BTB/RTO contact: open

After about 5 seconds:

LED display: YY. (amount of current, blinking point for CPU o.k.)

BTB/RTO contact: closed

|

|

2.

|

Switch on personal computer

|

|

3.

|

Start commissioning software

|

|

4.

|

Click on the interface (COM1... COM10) that is used for communication with

the servo amplifier.

The parameter are transmitted to the PC.

|

|

5.

|

Click on the radio button "SW-disable" at bottom right or press the function

key F12.

NO ENABLE now stands in the AXIS status field.

|

Basic setting

The servo amplifier remains disabled and the main power supply is switched

off.

|

1.

|

Set up basic parameters (address, ballast details, line/mains supply voltage

etc.):

- Click on the BASIC SETTINGS button

- Alter the fields, if necessary

-

Click on APPLY and then on OK

|

|

2.

|

Select motor:

- Click on the MOTOR button below the picture of the motor

-

Open the motor selection table, by clicking on the arrow in the field

NUMBER-NAME

- Click on the motor that is connected

- Click on APPLY

- Answer

the query about the brake

- Answer the query "Save to EEPROM/Reset" with

NO

(the data are in the RAM and will be permanently saved later)

|

|

3.

|

Select feedback (resolver, encoder):

- Click on the FEEDBACK button

- The

values that are displayed correspond to the default data that you have

loaded

for the motor.

- Alter the fields, if necessary

- Click on APPLY

and then on OK

|

|

4.

|

Set up the encoder emulation (ROD, SSI):

- Click on the ROD/SSI/ENCODER

button

- Select the desired encoder emulation

- Set up the corresponding

parameters in the right half of the window

- Click on OK

|

|

5.

|

Configure the analog inputs/outputs:

- Click on the I/O ANALOG button

- Select

the desired ANALOG-FUNCTION

- Set the scaling relative to 10V for the analog

input that is used.

- Set up the required output signals for AN OUT 1 and

AN OUT2

- Click on OK

|

|

6.

|

Configure the digital inputs/outputs:

- Click on the I/O DIGITAL button

-

Assign the required functions to the digital inputs (left half of window)

and enter the auxiliary variable X if it is necessary.

- Assign the required

functions to the digital outputs (right half of window)

and enter the

auxiliary variable X if it is necessary.

- Click on OK

|

|

7.

|

Save parameters:

- Click on the button

button

- Answer the query RESET AMPLIFIER

with YES

|

|

8.

|

Click on the radio button "SW-disable" at bottom right or press the function

key F12.

NO ENABLE now stands in the status field for AXIS

|

If you want to use the position control of the servo amplifier, then you

must enter the specific parameters for your drive:

|

1.

|

Axis type:

- Click on the POSITION button

- Click on the POSITION DATA button

- Select the axis

type (linear, rotary or modulo)

|

|

2.

|

For the axis type MODULO: enter the parameters Modulo-Start-Pos. and Modulo-End-Pos.

|

|

3.

|

Resolution:

- Enter the denominator and numerator for the resolution. Here

you adjust the path

traversed by the load in positioning units (length

unit for linear axes, or °mech.

for rotary axes) to match the number

of turns of the motor.

Only integer entries are permitted.

Example 1:

Ratio = 3.333 mm / turn

=> resolution = 10000/3 µm/turn (all other path

entries in µm)

or

=> resolution = 10/3 mm/turn (all other path entries in

mm)

Example 2: Ratio = 180 °mech./turn

=> resolution = 180/1 °mech./turn

(all other path entries in °mech)

|

|

4.

|

vmax:

- Enter the maximum traversing speed for the load that results from

the resolution

at the rated speed of the motor. The dimensional unit is

derived from the

resolution (°mech./sec or length units/sec).

Example 1:

resolution = 10000/3 µm/turn, nnom = 3000 turns/min

=> vmax = resolution

* nnom = 10000/3 * 3000 µm/min = 10 000 000 µm/min

or

=> vmax = resolution

* nnom = 10/3 * 3000 mm/min = 10 000 mm/min

Example 2: resolution = 180 °mech/turn,

nnom = 3000 turns/min

=> vmax = resolution * nnom = 180 * 3000 °mech/min

= 9000 °mech/s

|

|

5.

|

t_acc/dec_min:

- Enter the time in ms that the drive requires, with the

mechanically permissible maximum acceleration,

to accelerate from zero

speed to vmax.

|

|

6.

|

InPosition:

- Enter the window for InPosition. This value is used for the

InPosition message.

The dimensional unit is derived from the resolution

(°mech. or length unit).

Typical value: e.g. approx. resolution * 1/100

turn

|

|

7.

|

max. following error:

- Enter the window for the following error. This value

is used for the message

FOLLOWING ERROR. The dimensional unit is derived

from the resolution

(°mech. or length unit).

Typical value: e.g. approx.

resolution * 1/10 turn

|

|

8.

|

Save parameters:

- Click on the button

button

- Answer the query RESET AMPLIFIER

with YES

|

Optimization of the control loops

The basic setting must be finished.

Preparation

|

1.

|

OPMODE:

Set the OPMODE "1,analog speed" (screen page AMPLIFIER)

|

|

2.

|

Setp. function:

Set the analog I/O-function to "0,Xsetp=An In 1" (screen

page ANALOG-I/O)

|

|

3.

|

Save the parameters:

- Click on the button (screen page AMPLIFIER)

button (screen page AMPLIFIER)

- Answer the query

RESET AMPLIFIER with YES

|

|

4.

|

An In 1:

Short-circuit the setpoint input 1 or apply 0V to it

|

|

5.

|

OSCILLOSCOPE:

Channel1: n_act Channel2: I_act (screen page OSCILLOSCOPE)

|

|

6.

|

Reversing mode:

Go to the screen page OSCILLOSCOPE/SERVICE/PARAMETER and set the

parameters for reversing mode to values that are safe for your machine,

also when the positioning control loop is switched off (approx. 10% of

the final limit speed).

|

|

|

During operation of the service function "Reversing mode" the analog setpoint

input is switched off and the internal positioning control is disabled.

Make sure that the individual motion of the selected axis is possible without

any hazard.

For safety, only operate the ENABLE signal of the amplifier

with an interlock switch, and check the EMERGENCY STOP function for this

axis.

|

Optimizing the current controller

Screen page CURRENT CONTROLLER

|

1.

|

If a suitable amplifier-motor combination is used, the current controller

will already have a stable setting for almost all applications.

|

|

2.

|

Ipeak:

- Reduce Ipeak to the rated value for the motor (protection of the

motor)

|

|

3.

|

Switch on the mains/line power.

|

|

4.

|

Provide the analog setpoint:

- Analog-In 1 = 0V

|

|

5.

|

Enable the amplifier:

- High signal at Enable input X3/15. In the AXIS status

field: NO SW-EN

- Click on the SW-Enable radio button. ENABLE now stands

in the AXIS status field.

The motor now stands under speed control, with

n=0 rpm. If the current controller is not stable in operation (motor oscillates

with a frequency clearly above 100Hz), please contact our applications

department.

|

Optimizing the speed controller

Screen page SPEED CONTROLLER

|

1.

|

SETP. -OFFSET:

Leave the amplifier enabled. If the axis is drifting, alter

the parameter Setp.-Offset until it stands still (or use the function AUTO-OFFSET).

|

|

2.

|

SETP. RAMP +/-:

The setpoint ramps are used to smooth the setpoint input (filter effect).

Set the mechanical

time constant for the complete system, i.e the rise time or ramp gradient

for the speed from 0 to ncmd.

As long as the ramps that are set are shorter

than the mechanical response time for the complete system, the response

speed will not be affected.

|

|

3.

|

LIMIT SPEED:

Set the desired final limit speed.

|

|

4.

|

KP/Tn:

Increase KP until the motor starts to oscillate (audible, and visible

on the oscilloscope) and then reduce KP again until the oscillations

have

definitely stopped and stability is assured.

Use the motor-specific default

value for Tn.

|

|

5.

|

Start reversing mode:

Start the reversing mode (F8, v1/v2 approx. +/-10% of nnom for the

motor).

Observe the speed response on the oscilloscope. If the settings

are correct,

there must be a stable step response in both directions.

|

|

|

|

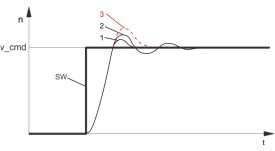

Diagram: Step response

n = speed

SW = setpoint

t = time

1 = optimum

2 = KP too high

|

|

6.

|

KP:

You can produce a fine tuning of the speed response by cautiously increasing

KP.

Aim: the smallest overshoot, but still retaining good damping.

A larger

total moment of inertia make it possible to use a larger value for KP.

|

|

7.

|

PID-T2:

You can dampen out disturbances, such as a small amount of play

in the gearing,

by increasing PID-T2 to about 1/3 the value of Tn.

|

|

8.

|

FEEDBACK:

You can further improve the smooth running by using FEEDBACK,

especially for

small drives with a low torque.

|

|

9.

|

End reversing mode:

Finish the reversing mode operation (F9).

|

Set up the correct, motor-specific value for Ipeak (current controller)

again. Start up reversing mode again, and observe the step response. If

there is any tendency to oscillation, reduce KP slightly.

Save the present parameter set in the EEPROM. Click on the button.

button.

Optimizing the position controller

Screen page POSITION CONTROLLER

Preparation

|

1.

|

OPMODE:

Select OPMODE 8 (screen page AMPLIFIER)

|

|

2.

|

Position the load in a middle position:

The aim is, to use the Jog Mode

function to move the load to approximately the middle of the motion path.

-

Click on the POSITION button

- Click on the HOMING button

- Check that the parameter v

(Jog Mode) is set to 1/10 of the

preset speed limit vmax. The sign of

"v" determines the direction.

Alter the value if necessary, and click

on APPLY.

- Start the function JOG MODE by using the function key F4 and

move the load to approximately the middle of the motion path

WARNING:

If the drive moves in the wrong direction, release the F4 function key

and change the sign of the parameter "v" (Jog mode).

Use F4 again to

move the load to approximately the middle of the motion path.

|

|

3.

|

Set reference point:

- Set the homing type to activate "0, set reference point".

Start the homing run. The momentary position is set as the reference point.

-

Stop the homing run

- Click on the radio button "SW-disable" in the amplifier

window

|

|

4.

|

Define test motion blocks:

- Click on the POSITION button

- Click on the POSITION DATA button

-

Click on the MOTION TASK TABLE button and select task 1. Enter the

values from the table below,

then select task 2 and

enter the corresponding values.

|

|

|

|

Task 1

|

Task 2

|

|

units

type

s_cmd

v_cmd_source

v_cmd

t_acc_tot

t_dec_tot

ramp

next motion task

next

number

acc./dec.

start condition

APPLY/OK

|

SI

REL setpoint

+10% of total path

digital

10% of vmax

10 * t_acc/dec_min

10

* t_acc/dec_min

trapeze

with

2

to target position

immediately

click

|

SI

REL setpoint

-10% of total path

digital

10% of vmax

10 * t_acc/dec_min or

amax / 10

10 * t_acc/dec_min or amax / 10

trapeze

with

1

to target position

immediately

click

|

|

5.

|

Save parameters:

- Click on the button

button

- Answer the query RESET AMPLIFIER

with YES

|

Optimization

|

|

The starting of motion tasks with the aid of commissioning-software functions

is only permitted in combination with an interlock device according to

EN12100, that operates directly on the drive circuitry.

|

|

1.

|

Start motion task:

- Click on the POSITION button

- Select motion task 1 on screen

page POSITION DATA, click on START, motion task 1 is started and, because of the

definition

of the motion task sequence, the drive moves in position-controlled reversing

operation.

|

|

2.

|

Optimize parameters (Click on the POSITION DATA button)

|

|

3.

|

PID-T2, FEEDBACK:

The speed controller is not used in OPMODES4, 5 and 8.

The position controller includes an integral speed controller, that takes

on the preset parameters for PID-T2 and FEEDBACK from the screen page "SPEED CONTROLLER".

|

|

4.

|

KP, Tn:

If KP is set too low, the position controller tends to oscillate.

Use the value for the optimized speed controller for KP. Tn should be 2...3

times as large as the Tn value for the optimized speed controller.

|

|

5.

|

KV:

The acceleration behavior of the motor should be well damped (no tendency

to oscillation) with a minimum following error. If KV is larger, the tendency

to oscillation increases. If it is smaller the following error increases

and the drive becomes too soft. Vary KV until the desired response is achieved.

|

|

6.

|

FF:

The integral component of the control loop is in the position controller,

not the speed controller, so no following error results at Jog Mode (pure

proportional control). The following error that arises during acceleration

is affected by the FF parameter. This error is smaller if the FF parameter

is increased. If increasing FF does not produce any improvement, then you

can increase KP a little, to make the speed control loop somewhat stiffer.

|

If the drive does not run satisfactorily under position control, first

look for external causes such as:

-

mechanical play in the transmission chain (limits the KP)

-

jamming or slip-stick effects

-

self-resonant frequency of the mechanical system is too low

-

poor damping, drive is too weakly dimensioned

before trying to optimize the control loop again.