Screen page "Position Data"

For each one of the positioning tasks you must define motion tasks. These

motion tasks can be selected by a motion task number, and are stored in

the servo amplifier.

|

Motion task

|

Stored in

|

Precondition for storing

|

Comments

|

|

1...180

|

EEPROM

|

output stage disabled

|

permanently stored

|

|

192...255

|

RAM

|

none

|

volatile storage

|

When the servo amplifier is switched on, the RAM motion blocks 192...255

are automatically pre-loaded with the parameters of the EEPROM motion blocks

1...64.

Number

Entry of a motion task number, to start the motion task from the PC.

Motion task table

A new window appears, in which all motion tasks are represented in tabular

form.

All motion task parameters can be entered in the table directly. The following

operations are available:

The clipboard operations cut, copy and paste are only possible for complete

rows, i.e. for these operations the appropriate row must be selected. The

deletion is possible both, row- and cellwise. A line can be selected either

by clicking on the row number, or through the keyboard shortcuts <Shitft>+<Space>

(similar to Microsoft Excel). All Edit operations are available through

the Windows standard keyboard shortcuts.

Input via the screen page"Motion task parameters":

Double-clicking a line number in the table opens the screen page for the

associated motion task. The use of the dialogue "Motion task parameters"

in relation to older versions of the software changed concerning the buttons

"OK", and "Cancel".Compared to older versions of the software, the functions

of the buttons "OK" and "APPLY" have changed. By clicking these buttons,

the changes are no longer saved to the flash EEPROM but the values in the

associated table are changed instead. Writing the changes to the EEPROM

is possible with the buttons "OK" or "APPLY" on the screen page "Motion

task table"

Start

|

ASCII: MOVE

|

Default: -

|

valid for OPMODE 8

|

Start the motion task that has the number that can be seen in the NUMBER

field. The amplifier must be enabled (input X3/15 has a High signal).

|

|

The SW-enable is automatically set when the motion task starts. The motion

task is only started in OPMODE8. However, the SW-enable is set in all OPMODES.

The drive can therefore be accelerated by an analog setpoint that is applied,

if the START command is executed in OPMODES 1 or 3.

The motion task is not

started if the target position is beyond the defined SW-limit switches

(warning messages n06/n07 and n08)

|

Stop

|

ASCII: STOP

|

Default: -

|

valid for OPMODE 8

|

Stops the current motion task. The SW-enable remains set!

Axis type

|

ASCII: POSCNFG

|

Default: 0

|

valid for OPMODE 8

|

Here you select whether the axis is to be operated as a linear or a rotary

axis.

v_max

|

ASCII: PVMAX

|

Default: 100

|

valid for OPMODE 8

|

This parameter is used to adjust the maximum speed of movement to suit

the limits of the operative machinery. The calculation of the upper setting

limit depends on the final limit speed of the drive. The value that is

entered is used as a limit for the "v_setp" entry in the motion tasks.

During commissioning, you can limit the speed by using v_max (without changing

the setting for the motion blocks). A lower value of v_max overrides the

v_setp of the motion tasks.

t_acc/dec_min / a max

|

ASCII: PTMIN

|

Default: 1 ms

|

valid for OPMODE 8

|

A drive is always so dimensioned that it can provide more power than the

application requires. This parameter determines the limit for the maximum

mechanical acceleration time to v_max, that must not be exceeded by the

drive. This time is simultaneously valid as the minimum limit for the entry

"t_accel_tot" (acceleration time from 0 to v_setp) and "t_brake_tot" (braking

time from v_setp down to 0) for the motion tasks.

Depending on the setting

of acceleration unit you can enter either the acceleration time or the acceleration in the

dimensional unit that has been selected.

InPosition

|

ASCII: PEINPOS

|

Default: 4000

|

valid for OPMODES 4,5,8

|

Sets the InPosition window. Determines at which distance from the set position

the "InPosition" message should be reported. The drive moves precisely

to the target position.

Modulo-Start-Pos.

|

ASCII : SRND

|

Default : -231

|

valid for OPMODES 4,5,8

|

|

This parameter is used to define the start of the range of movement for

a modulo axis.

The end of the range is defined by the parameter Modulo-End-Pos.

|

Modulo-End-Pos.

|

ASCII : ERND

|

Default : 231-1

|

valid for OPMODES 4,5,8

|

This parameter is used to define the end of the range of movement for a

modulo axis.

The start of the range is defined by the parameter Modulo-Start-Pos.

Position register

A programmable register that can have various functions assigned to it.

Make

changes only while the amplifier is disabled + reset.

SW limit-switches 1 / 2

The software limit-switches from part of the monitoring functions of the

position controller.

|

SW limit-switch 1

|

The monitoring checks whether the actual position value is lower than the

preset value (the negative direction of travel is now inhibited – You have

to leave limit-switch 1 by moving in the positive direction. ).

|

|

SW limit-switch 2

|

The monitoring checks whether the actual position value is higher than

the preset value (the positive direction of travel is now inhibited – You

have to leave limit-switch 1 by moving in the negative direction.)

|

The drive brakes with the emergency ramp, and remains at standstill under

torque.

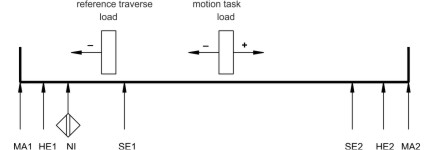

The principle of positioning the software limit-switch can be seen

in the diagram below:

|

|

Legend

MA1 : Machine stop, left

HE1 : Hardware limit-switch, left

NI : Zero pulse initiator

(reference)

SE1 : Software limit-switch 1

SE2 : Software limit-switch 2

HE2 :

Hardware limit-switch right

MA2 : Machine stop right

+ : Positive count direction

- :

Negative count direction

|

|

ASCII: SWCNFG (set, bit variable)

|

Default: 0

|

valid for all OPMODES

|

|

ASCII: (position)

SWE1, SWE2, SWE3, SWE4, SWE5

|

Default: 0

|

valid for all OPMODES

|

Configuration variables for the position register. SWCNFG is a binary-coded

bit-variable, and is transferred to the ASCII terminal program as a decimal

number.

Resolution

|

ASCII: PGEARI (numerator)

|

Default: 10000

|

valid for OPMODE 8

|

|

ASCII: PGEARO (denominator)

|

Default: 1

|

valid for OPMODE 8

|

The entry for the resolution of the motion tasks is in µm/Revolution. The

resolution can be defined at will, through the entries for the numerator/denominator.

Make

changes only while the amplifier is disabled + reset.

Examples:

An entry

of 10000/1 produces a resolution of 10 mm/turn

An entry of 10000/3 produces

a resolution of 3.333 mm/turn

Rotary table with geared motor, i = 31 (31

motor turns for one turn of the table)

– The entry 360/31 provides operation

with position entries in degrees, without rounding off.

The maximum range of movement is limited to +/- 2047 motor turns. If a

larger range (+/- 32767) is required, please consult our applications department.

GMT

Opens the graphical motion tasking.

Graphical motion tasking is an advanced

feature that lets you easily edit motion tasks with its graphical interface.

You can command multiple motions, process I/O, make decisions, add time

delays and modify drive process variables. The environment is easy to use,

allowing you to program in an intuitive flow-chart.

Motion tasking has been

supported by the amplifier since the product was introduced in 1998. In

its original form, motion tasking supported only chained moves in sequences

executed either once or in infinite loops. Graphical motion tasking extends

the capabilities of moiton tasking by adding looping, comparing (<, =,

>, etc.), calling functions and setting process variables.